Several materials

were employed for the building of the Colosseum, all of them easily found or produced in the Roman area: first of all there is the travertino, a limestone, then tuff for the other pillars and radial walls, tiles for the floors of the upper storeys and the walls; finally, concrete (a.k.a. cement) for the vaults.

Travertine, a limestone that the Romans called lapis Tiburtinus, is a sedimentary stone made essentially of calcite, deposited by calcareous waters. Its colour is whitish, slightly yellow or reddish. It is still used for building, for floors or as a veneer. It is common in Tuscany, Umbria, Lazio, Marche. The stone can stand a pressure of 226/298 Kg/cmq, depending on its quality. The travertino of the Colosseum was quarried from Tibur (today Tivoli, a town about 20 Km from Rome); it was used for the main pillars, the ground floor and the external wall. A road was built for the transport of the stone from Tibur.

Tuff (tofus in Latin, tufo in Italian, sometimes tufa in English, meaning in general a porous stone consolidated and stratified, though the tendency is to use tufa for calcareous stone deposited by waters and to restrict tuff to volcanic ash) is a stone produced by the cementing of vulcanic material fallen after eruptions. Its colour is gray, yellowish, greenish or brown. It is used in the preparation of special cements and as a building stone (peperino).

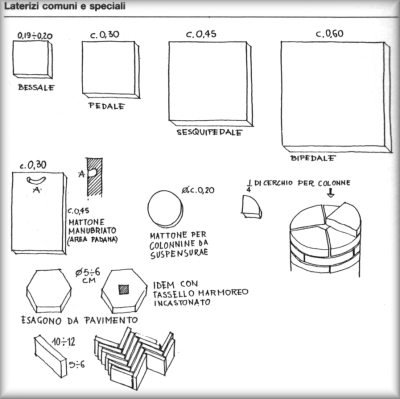

Tiles and bricks were produced with clay mixed with water and often with sand, straw and finely ground pozzolana. The mixture was pressed by hand into a wooden mould, and dried first in the sun. The tiles had to be turned over often, so as that they would not bend.

After a long time of drying under cover, the tiles were placed in the oven and baked at 800 C°. They were produced in standard sizes (full and hollow bricks, tiles for roofs etc). Bricks could be used in wall structures, as roofing and as filling, often by using the leftovers of former works.

Roman Cement (most of the info from Benjamin Herring “The secrets of Roman Concrete” – Constructor, Sept. 2002 – in http://www.romanconcrete.com/ )

Cement, or concrete, is a building material with a binding agent, usually produced by mixing finely ground limestone and clay. It reacts to water by forming a cement that hardens to the consistency of stone. When mixed with sand, small stones or pebbles takes the name of concrete aggregate (or beton).

Mortar (malta) is a mix of a binding agent (calcia, cement) and water (malta semplice) or with water and sand (m. composta). It hardens when exposed to air (malta aerea) and also in water (malta idraulica).

Lime is a binding agent that Romans obtained by heating limestone – which contains calcium, carbon and oxygen – in a kiln. Limestone undergoes a chemical reaction in which the carbon and some of the oxygen will be driven off as carbon dioxide, leaving a highly reactive product known as quicklime, or calcium oxide.

Quicklime in water starts a bubbling, heat-producing chemical reaction which yields a white colloidal paste, called hydrated lime or slaked lime. In chemical terms: CaCO3 – calcium carbonate – when heated becomes CaO and liberates CO2 (carbon dioxide). CaO + water H2O becomes Ca(OH)2, that is calcium idroxide (slaked or hydrated lime). Concrete is produced by mixing that paste with river sand or pozzolana.

The quicklime was converted into lime paste by immersing it in water. By adding water to the lime, Romans produced:

- lime putty, thick and greasy; used as a binder for the cement;

- lime milk, with 20/30% of water, used for the paints;

- lime water, clear and disinfectant, used for medicinal purposes.

A few more words on Roman Cement

Romans had two distinct types of concrete mortar. One was made with simple lime and river sand, mixed at a ratio of three parts sand to one part lime.

The other type used pozzolana instead of river sand and was mixed at a ratio of two parts pozzolana to one part lime.

There was no doubt as to which was superior: the pozzolanic mortar. Pozzolana, the vulcanic ashes (pulvis puteolana in Latin) took its name from the Pozzuoli region by the Bay of Naples, where it was found, and it was a truly magical substance.

Vitruvius, an engineer and architect for the Emperor Augustus, wrote 10 books on architecture and engineering. He devotes an entire chapter in his second book to pozzolana, stating that “there is also a kind of powder which from natural causes produces astonishing results. It is found in the neighbourhood of Baiae and in the country belonging to the towns round about Mount Vesuvius.

This substance, when mixed with lime and rubble, not only lends strength to buildings of other kinds, but even when piers of it are constructed in the sea, they set hard under water.”

Scientists today know exactly what Vitruvius’s “powder” was: volcanic ash—and the Romans had it in prodigious abundance. What is the secret of the special ingredient?

Let’s begin by looking at the modern technical definition of pozzolana, which is: A siliceous or aluminous material which in itself possesses no cementitious value, but will, in a finely divided form, and in the presence of moisture, chemically react with calcium hydroxide at ordinary temperatures to form compounds possessing cementitious properties.

Translated: by using volcanic ash in the place of river sand in their concrete, the Romans were anticipating the process by which modern Portland cement chemically bonds lime to clay through the application of heat. But finely divided pozzolana must be amorphous (glassy) to chemically react. How was this possible?

Because the volcano had already heated the pozzolana for them! In the words of Tim Dolen, a pozzolana expert and research civil engineer at the U.S. Bureau of Reclamation, “the pozzolana was calcined by the volcano,” enabling it to chemically react with calcium hydroxide in slaked lime, no heating required.

Here are some links on Roman engineering and on the materials:

- The Colosseum: Quality and efficiency of construction, by Giovanni Manieri Elia (with an English translation)

- On Roman Waterworks

- An article on the Aqueducts of Rome under Augustus

- An article on Water and Wastewater System in Imperial Rome

- Best website on Roman cement: The Roman Pantheon: The Triumph of Concrete

by David Moore, P.E.: http://www.romanconcrete.com/ - On the concrete aggregate (calcestruzzo):

- Wikipedia on Roman Concrete

- And another one on concrete

- Why Roman concrete is so durable?

- An interesting study by academics Cerone, Croci and Viskovic about the structural behaviour of the Colosseum over the centuries